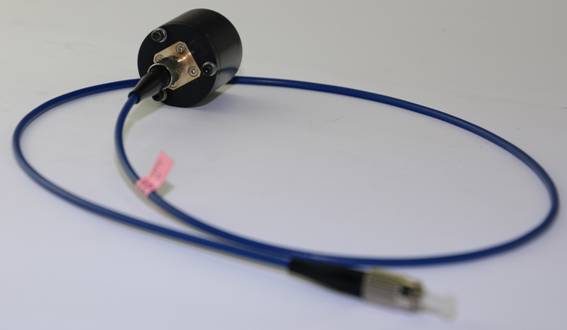

Fiber Coupler |

| Fiber Coupling Efficiency - DPSS Laser | |||

| 100µm MM Fiber | 200µm MM Fiber | 400µm MM Fiber | |

| TEM00 Beam Mode | >75% | >80% | >90% |

| Multi transverse mode | >70% | >80% | >90% |

| Fiber Coupling Efficiency - Diode Laser | |||

| Single-Mode LD | >75% | >80% | >90% |

| Multi-Mode LD | >70% | >80% | >90% |

| Laser Products | |||

| Model | Focus the Beam to | Connector | Fiber can be used |

| FCR-100-PC | <100μm | FC/PC | ≥100μm MM fiber |

| FCR-100-SMA | <100μm | SMA905 | ≥100μm MM fiber |

|

To maximize the amount of laser light entering the fiber, the coupler is aligned before shipping, but couplers may become misaligned during shipping and when used or stored in areas with vibration or large changes in temperature. If your laser is not producing the expected level of output at the output aperture of the optical fiber, realignment may be needed. For lasers with output power above 3W, we strongly recommend using the SMA connector type in order to maximize coupling efficiency and prevent damage to the fiber. For low-power lasers (≤500 mW), the FC/PC connector type ensures consistent rotational orientation. This provides better repeatability in terms of coupling efficiency if the fiber is to be removed and re-inserted multiple times. SMA connectors are preferable for lasers with higher power, but they do not provide this benefit. |

|||

|

|

|